Lubricant Emissions and Lifecycle

The Hidden CO2 Footprint of Lubricants

Lubricant Emissions and Lifecycle Analysis

In In our previous article, we explored how businesses navigate emissions regulations and reporting frameworks. As industries work towards sustainability, understanding where emissions originate is key. While companies often focus on direct and energy-related emissions, one overlooked contributor is lubricants - essential for industrial operations yet responsible for significant greenhouse gas (GHG) emissions throughout their lifecycle.

This article uncovers the hidden CO2 footprint of lubricants, detailing how emissions accumulate from production to disposal, which industry actors are involved, and how they align with Scopes 1-3 emissions reporting.

Lubricants - A Hidden Source of Emissions

Lubricants are indispensable in machinery and transport, reducing friction, preventing wear, and improving efficiency. However, their carbon footprint extends far beyond their use. From crude oil extraction to refining, distribution, application, and disposal, each phase contributes to emissions - some directly emitted and others embedded in the supply chain.

One liter of lubricant oil can generate over 3.5 kg of CO2 over its lifecycle if disposed of through traditional combustion. However, this number varies based on factors such as raw material sourcing, refining methods, logistics, operational efficiency, and disposal practices. Optimizing oil change intervals and selecting sustainable disposal methods - such as re-refining instead of incineration - can significantly reduce emissions and enhance sustainability.

In heavy industry and logistics, lubricants represent a notable share of operational emissions. Companies aiming for Net Zero must factor in lubricant lifecycle emissions to get a complete sustainability picture.

Lifecycle Emissions of Lubricants

The Lifecycle Assessment (LCA) methodology helps quantify emissions across a lubricant’s entire life. The lubricant lifecycle is often divided into two main phases: Product Manufacturing and Delivery (Steps 1-4) and Product Use and Disposal (Steps 5-6). In industry terminology, the first phase is referred to as Cradle-to-Gate, covering everything from raw material extraction to the point where the product is ready for use. The full lifecycle, from raw material extraction to disposal, is referred to as Cradle-to-Grave (see Picture 1).

Raw Material Extraction – Emissions arise from crude oil extraction and transportation.

Refining & Processing – Refining crude oil into base oils and processing additives.

Manufacturing & Blending – Producing lubricants involves energy-intensive blending, additives production, and packaging.

Distribution & Logistics – Transportation from refineries to end-users generates emissions.

Usage in Equipment – Lubricant degradation, evaporation, and leaks contribute to Scope 1 emissions, affecting efficiency.

End-of-Life (Disposal & Recycling) – Waste oil disposal, incineration, or re-refining adds another emissions layer.

By breaking down emissions at each phase, businesses can identify opportunities for reduction and enhance sustainability efforts (see Picture 1).

Picture 1. Product Lifecycle of a Lubricant

Applying Scopes 1-3 to Lubricant Emissions

Understanding who is responsible for emissions at each stage is crucial for sustainability reporting. The Greenhouse Gas Protocol (GHG Protocol) categorizes emissions into three scopes:

Scope 1 (Direct Emissions): Lubricant evaporation, leaks, and combustion emissions during use.

Scope 2 (Indirect Energy Emissions): Energy used in lubricant production, blending, and storage.

Scope 3 (Value Chain Emissions): Emissions from raw material extraction, manufacturing, transportation, and disposal—typically the largest contributor in the lubricant lifecycle.

Companies must assess how emissions are distributed across industry actors to build accurate sustainability reports.

Industry Actors and Their Emissions Responsibilities

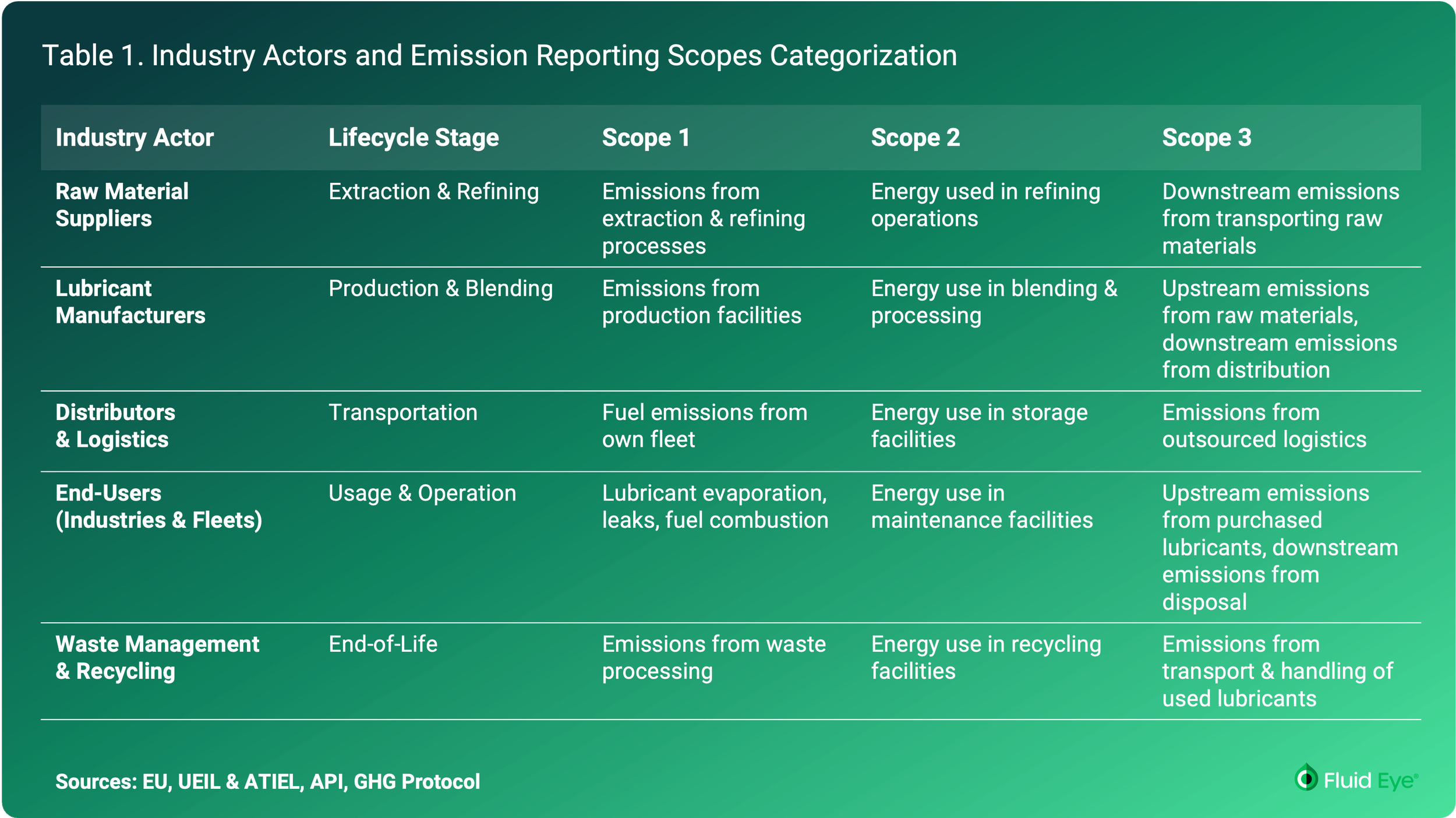

Different stakeholders contribute to and are responsible for lubricant-related emissions. The table 1. below illustrates how Scope 1, 2, and 3 emissions are categorized for each industry actor.

Table 1. Industry Actors and Emission Reporting Scopes Categorization

This breakdown highlights how the same emissions can appear in multiple companies' reports under different Scopes, reinforcing the interconnected nature of emissions responsibility throughout the lubricant lifecycle.

Regulatory Frameworks and Lifecycle Analysis Models

Companies tracking lubricant emissions rely on standardized methodologies:

ISO 14040, 14044 & 14064 (LCA Standards) – Provide a structured approach to quantifying environmental impact across the lubricant lifecycle.

Greenhouse Gas Protocol (GHG Protocol) – Essential for categorizing Scope 1-3 emissions.

Product Carbon Footprint Methodologies (e.g., ATIEL & API TR 1533) – Industry-specific approaches to calculating lubricant-related CO2 emissions.

Compliance with these frameworks ensures transparent reporting and alignment with sustainability goals.

The Business Impact of Lubricant Emissions

For companies in heavy industry and logistics, integrating lubricant emissions into sustainability strategies offers clear benefits:

✅ Regulatory Compliance – Staying ahead of evolving EU and global regulations.

✅ Operational Efficiency – Optimizing lubricant performance reduces waste and emissions.

✅ Cost Savings – Efficient lubrication minimizes energy loss and equipment wear.

✅ Brand & ESG Leadership – Transparent reporting enhances investor and customer confidence.

Key Takeaways

Lubricants contribute significant hidden CO2 emissions across their lifecycle.

LCA models help quantify emissions at each phase from production to disposal.

Scopes 1-3 emissions apply differently to oil producers, manufacturers, users, and recyclers.

Adopting GHG Protocol and ISO standards ensures transparent reporting and sustainability compliance.

Navigating the Future Together

Lubricants play a significant role in industrial CO2 emissions, but their impact can be managed effectively. A well-planned lubrication strategy, extending lubricant lifetime, and utilizing advanced waste oil recycling methods can significantly reduce emissions - potentially achieving Net Zero.

The Net Zero Lubrication model by Fluid Intelligence offers a comprehensive approach to managing the entire lubrication lifecycle, delivering benefits such as improved operational reliability, cost savings, and measurable sustainability gains.

References and Sources

UEIL & ATIEL - Methodology for PCF Calculations of Lubricants and other Specialities

API - Technical Report 1533 - Lubricants Life Cycle Assessment and Carbon Footprinting

ISO 14040 - Environmental management — Life cycle assessment — Principles and framework

ISO 14044 - Environmental management — Life cycle assessment — Requirements and guidelines

Disclaimers

The views expressed in this article are those of the authors. We regret for any unintentional errors, omissions, or misinterpretations.

Author: Mika Perttula (CEO - Fluid Intelligence Oy)

*** KEEP ON READING ABOUT NET ZERO LUBRICATION ***

Net Zero Lubrication is a strategic mindset and model helping industrial companies to maximize operational performance while minimizing fluid-based CO2 emissions and costs. This model is based on managing the entire lubrication lifecycle from Emissions Management and Fluid Performance Optimization perspectives in three stages - 1) Lubrication planning, 2) In-Service oil lifecycle and performance maximization, and 3) End-of-life waste oil management.

Continue reading Net Zero Lubrication articles to gain deeper insights how companies are optimizing their businesses to become more sustainably compliant, competitive, and profitable. Go to Net Zero Hub.