Reconditioning and Services

Fluid Eye® provides solutions and services to all fluid optimization needs

Fluid Reconditioning

Impurity removal units provide effective ways to maximize oil performance and its lifetime. Units can be delivered together with Connected Oil® Monitoring service to enable real-time visibility to reconditioning process. Units are available for purchase or as a monthly service.

Remove solid and soft particles

Remove Water

Remove Soluble impurities like varnish (>2 µm)

Get real-time view, alerts and process documentation

“Oil maintenance is a reliable method to ensure stable, trouble-free operation.”

Markus Lehti, Maintenance Engineer, Keravan Lämpövoima

Fluid Eye®

NTF Mini

Fluid Eye®

NTF Mobile

Fluid Eye®

+ VITA ESP II

Additives and Chemicals

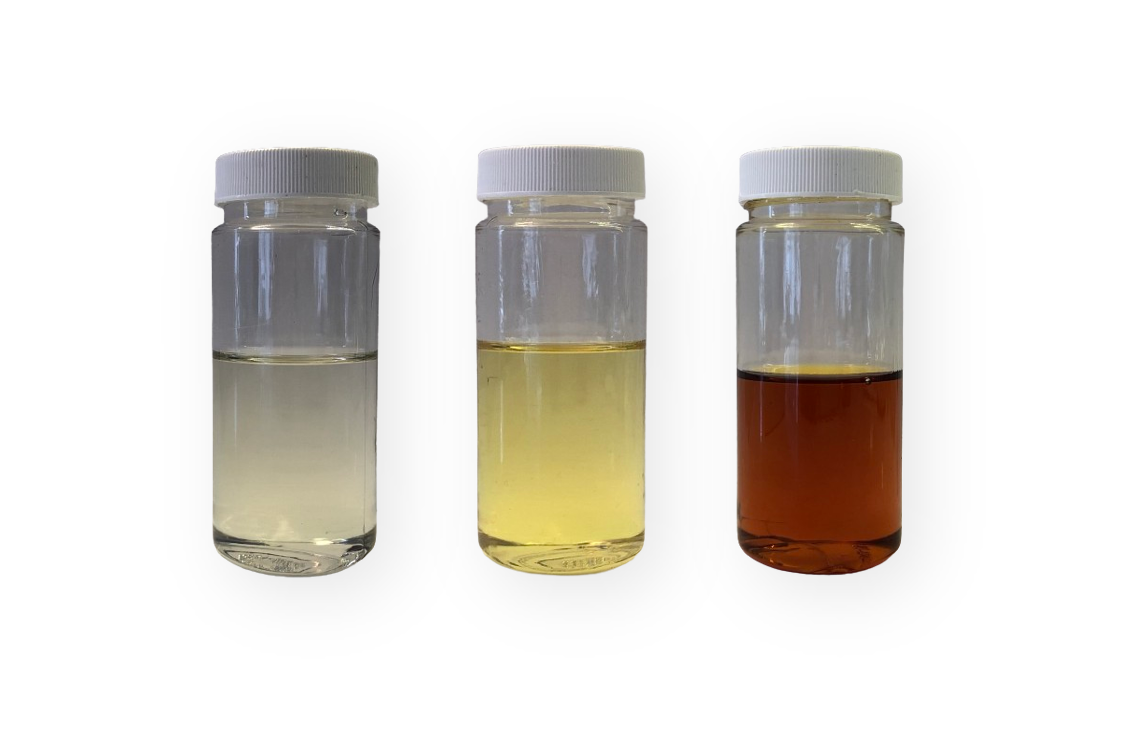

Additive top-ups and Chemicals Fluids and machines perform in harsh conditions stressed by extreme temperatures, impurities, water and other contaminants leading to accelerated oil aging and additive depletion.

Additive top-ups and chemical enhancers help to restore oil’s performance and extend its lifetime.

Prevent premature oil aging and oil changes

Increase lubricants performance and lifetime

Reduce total cost of ownership with efficient asset usage

Get expert support with lab and real-time monitoring based project documentation

Expert Services

Expert Services offers a range of fluid and machine performance related services. The services support daily activities e.g., operational reliability and maintenance, operations, process quality, site and fleet management or emissions management.

Get laboratory analysis and statements to your needs

Execute site audits for fluid and machine health

Carry out industrial fluids emission audits

Get tailored projects for your needs (e.g. system flushing)