Connected Oil® Monitoring

Real-time Oil Condition Monitoring (OCM) is a corner stone for ensuring critical assets and processes performance

Oil Condition Monitoring (OCM)

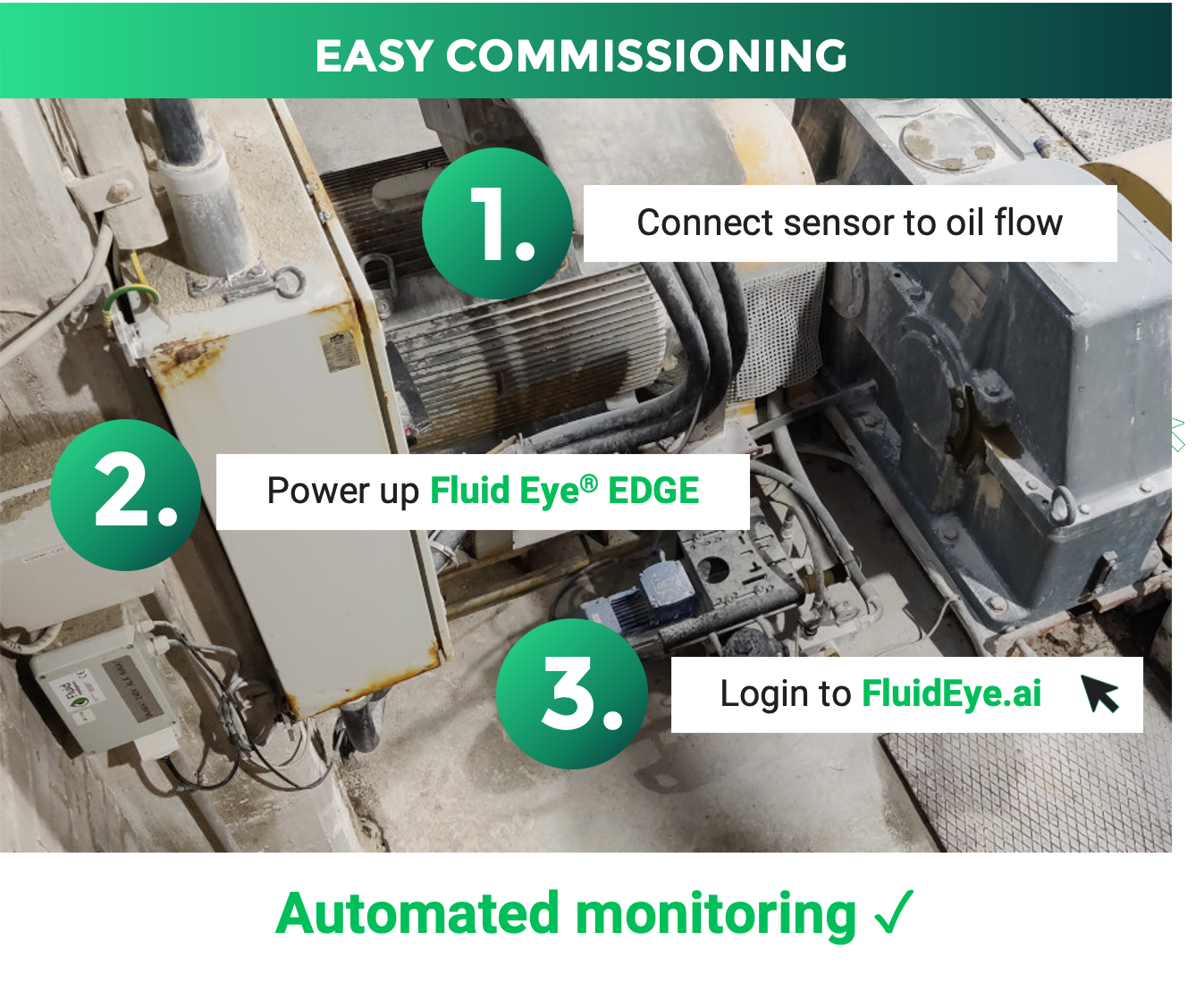

Connected Oil® Monitoring delivers 24/7 real-time visibility to critical machines and fluids operational performance. The service is optimized for continuous Oil Condition Monitoring and Lube Reconditioning Projects.

Lubricants, transformer, hydraulic and other fluids

Oil Quality Trend, Cleanliness and Chemical parameters

Get Actionable Advice for instant anomaly mitigation

See key events on a timeline and reports

“Applying proactive fluid performance monitoring and oil-reconditioning has been simple and cost-effective.“

Miikka Nurmi, Operation Manager

Fluid Eye® monitoring packages

-

Oil quality

Temperature

+ Pressure, flow, level

-

Particle counts & sizes

Particle classes

Humidity (rH%)

-

Water (ppm)

Oxidation

Antioxidants

TAN/TBN

Viscosity

+ Other customized parameters

Analysis and Advice

Analysis is a continuous process where key parameters, trends and multi-variable correlations are monitored constantly. Actionable Advice makes it easy to take early proactive actions with sound understanding to anomalies root-causes.

24/7 visibility to critical assets

Extended fluid lifetime and sampling interval

Less downtimes and machine failures

Reduced total-cost-of-ownership (TCO)

“Fluid Eye® Trend has increased reliability through real-time visibility to the process critical turbine oil’s performance.”

Toni Jokela, Power Plant Manager

Endless monitoring possibilities

Connected Oil® is a cost-effective solution to monitor oil quality trends, cleanliness, chemical and other key properties. The service delivers concrete benefits to multiple equipment and fluid combinations in over 15 different industries currently.

Monitored phenomena

Fluid quality and temperature

Mechanical failure indicators

Cleanliness classification and contaminants

Fluid aging and Oxidation

Varnish

Additive depletion

+ Other custom phenomena

Applicable equipment

Lubrication systems

Industrial Gears

Engines

Stationary Hydraulics

Mobile hydraulics

Transformers

+ Other fluid using equipment

Applicable fluid types

Lubricants

Transformer oils

Hydraulic oils

Bio-based lubricants

Additives, chemical enhancers

Fuels and bio-based fuels

Coolants, Solvents and Water

Monitoring packages

-

Oil quality

Temperature

+ Pressure, flow, level

-

Particle counts & sizes

Particle classes

Humidity (rH%)

-

Water (ppm)

Oxidation

Antioxidants

TAN/TBN

Viscosity

+ Other customized parameters