Data Centers, Energy & Oil: The Hidden Risk

The Hidden Power Risk in Data Centers: Why Transformer and Backup System Oils Matter

The Growing Power Challenge

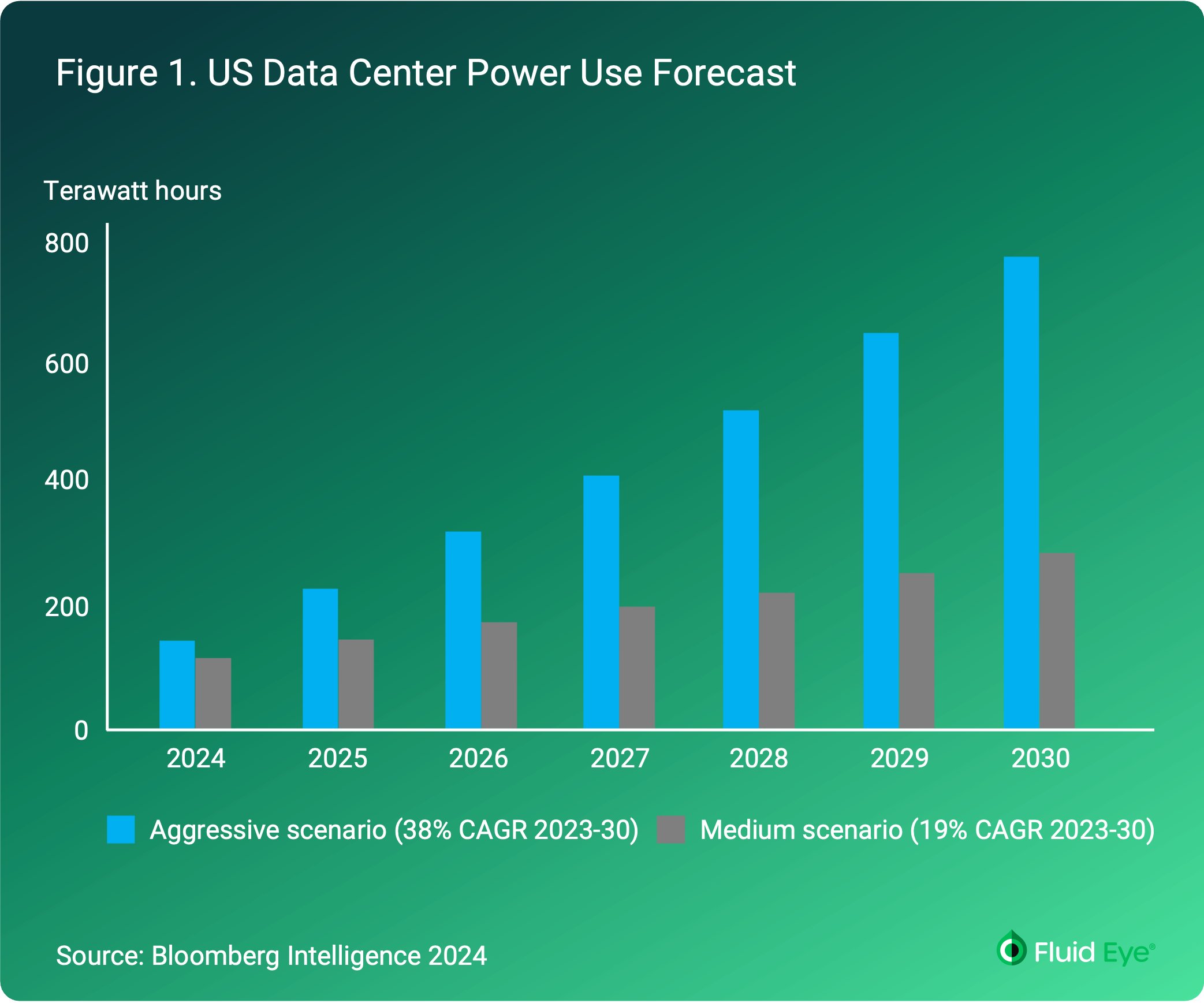

Figure 1. US Data Center Power Use Forecast (2023-2030)

The demand for data centers is skyrocketing, with electricity consumption expected to double by 2030 driven by cloud computing, AI, and the ever-growing demand for digital services (Figure 1. Example of the US Data Center Power Use Forecast 2023-2030). This rapid growth places increasing pressure on power reliability - not just from the grid but also within on-site infrastructure like transformers and backup power systems.

Forward-thinking executives and operations teams understand that ensuring uptime isn’t just about installing more infrastructure - it’s about keeping existing assets in peak condition. A critical yet often overlooked factor? Transformer and backup generator oils.

Without proper monitoring and maintenance, oil degradation can lead to unexpected failures, jeopardizing operations and causing costly downtime.

The Role of Transformer Oils in Power Stability

Transformers are the backbone of data center power distribution. They rely on insulating oils to prevent overheating and ensure smooth operation. Over time, however, these oils degrade due to oxidation, contamination, and moisture, which can lead to:

Reduced insulation performance, increasing the risk of electrical failures

Unplanned outages, disrupting critical IT operations

Unnecessary oil changes, leading to higher costs and waste

From Calendar-Based to Proactive Oil Maintenance

Traditionally, transformer oil changes are performed on a fixed schedule, leading to inefficiencies. Instead, real-time Oil Condition Monitoring (OCM) enables data centers to:

✅ Extend oil life, reducing maintenance costs

✅ Predict failures before they happen, avoiding downtime

✅ Improve sustainability, cutting oil waste and environmental impact

This shift from reactive to proactive maintenance ensures maximum uptime while cutting both costs and environmental impact.

Backup Power Systems: The Last Line of Defense

Most data centers have backup generators to safeguard against power grid failures. These systems are designed to activate instantly in case of a power grid failure. However, if these systems aren’t maintained correctly, they may not function when needed most.

Key Risks in Backup Generators

Oil degradation: Lubricants break down over time, reducing engine performance and causing wear

Fuel contamination: Diesel and gas fuels oxidize, forming sludge and deposits that clog injectors and filters

Startup failures: If oil or fuel quality has degraded, generators may fail to start, leaving data centers vulnerable

By integrating fluid condition monitoring, data centers can:

✅ Ensure backup power is always operational

✅ Reduce emergency maintenance costs

✅ Extend equipment life and improve overall reliability

Why Proactive Maintenance is the Future

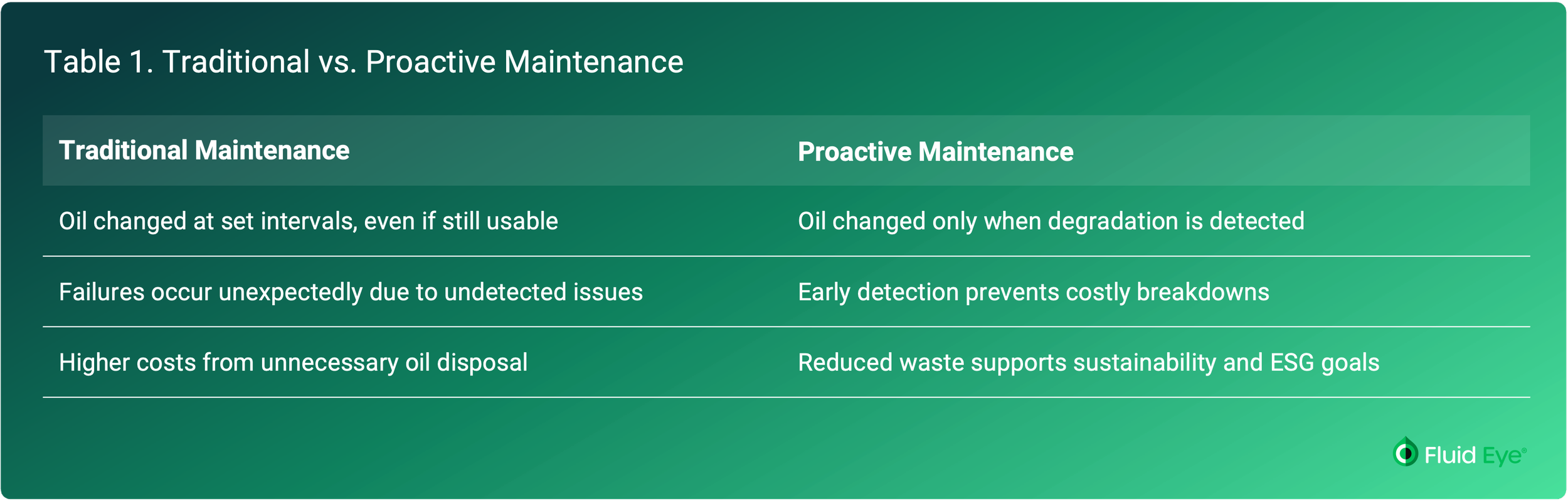

Traditional maintenance strategies rely on fixed schedules, leading to wasted resources and unexpected failures. Proactive maintenance, powered by real-time oil and fuel monitoring, enables a more efficient, cost-effective approach (Table 1.).

For operations teams, this means fewer disruptions. For CFOs and sustainability leaders, it means lower costs and improved ESG compliance.

Table 1. Traditional vs. Proactive Maintenance in Transformer Oils and Back-up Power Systems

Business Justification: Who Benefits and How?

Optimizing transformer and backup power system oils isn’t just an engineering decision - it’s a strategic advantage. In an era where power reliability is mission-critical, every stakeholder benefits from a smarter, more sustainable approach to fluid management.

Companies that invest in smarter lubrication strategies gain a financial, operational, and sustainability edge over competitors.

Table 2. Business benefits for stakeholders when Optimizing Transformer and Back-up Power System Oils

Key Takeaways

Power reliability is more than just infrastructure - it requires continuous monitoring and smart maintenance

Transformer oil degradation is a hidden risk - poor insulation can cause failures and downtime

Backup generators can fail when needed most - without proper oil and fuel management, startup issues arise

Proactive maintenance maximizes uptime - by using real-time monitoring, failures can be prevented before they happen

Sustainability and cost savings go hand in hand - extending oil life reduces waste and maintenance expenses

Conclusion

The rapid expansion of data centers brings new challenges, particularly in power reliability. Yet, many organizations overlook a critical failure point - the degradation of transformer and backup generator oils.

Forward-looking executives, operations and maintenance teams are already shifting from calendar-based maintenance to real-time Oil Condition Monitoring (OCM) and Net Zero Lubrication strategies. With this strategic move data centers can prevent failures, cut costs, and enhance sustainability.

Power reliability isn’t just about the grid - it’s about ensuring that every component, down to the last drop of oil, is performing at its best.