Fluid Optimization

Services

Fluid Eye® provides solutions and services to all fluid optimization needs

Emission Management

Industrial decarbonization begins with Fluid Management to minimize waste while maintaining maximum reliability

Simulation visualize current CO2 footprint and model future carbon reduction strategies easily

Net Zero Lube Assessment a complete Lifecycle Analysis of the lube’s Health, Emissions and Costs

Reporting automate annual fluid-based emissions documentation to fulfill regulatory requirements

“Monitoring machinery and maintaining oils has helped us to improve performance and extend oil change intervals considerably.”

Mikko Juvonen, Production Manager

Health Management

Fluid and Machine Health starts with a holistic view to the assets’ performance and proactive actions

Health Score easy Zero-to-100 indicator that makes lab data comparable among fleet and asset classes

Analysis get action recommendations for fluid’s performance improvements and lifetime extension

Report Hub store all your oil data in one place and create reports for multiple fleets and machines

“Oil health management is a reliable method to ensure stable, trouble-free operation.”

Markus Lehti, Maintenance Engineer, Keravan Lämpövoima

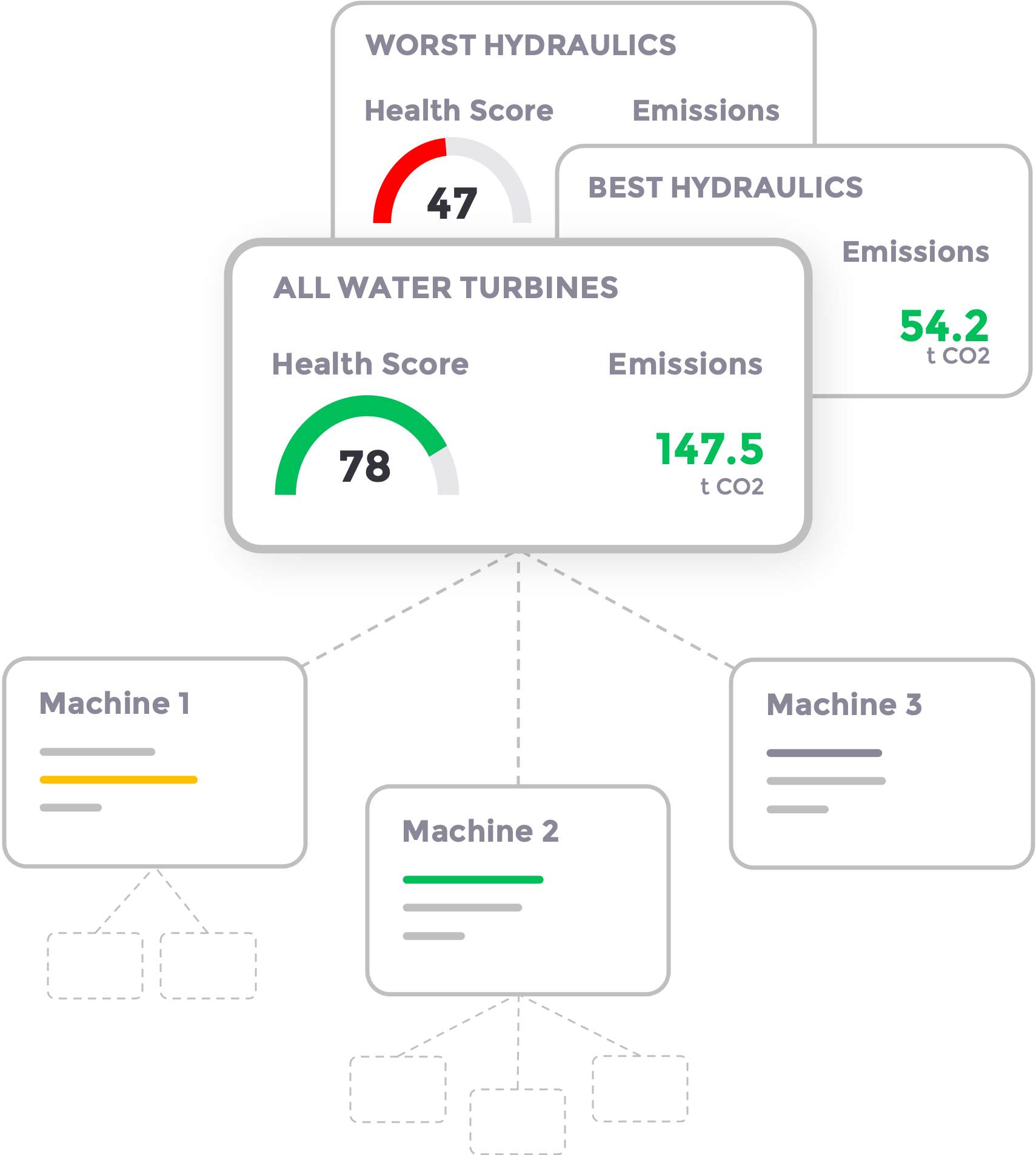

Fleet Management

Multi-fleet view to critical assets Health and Emissions is a foundation for enterprise-wide optimization

Fleet and Site Management manage all your assets easily in one view

Analytics and Reporting See easily Health and Emission KPIs, trends and changes in details

Benchmarking create easily fluid and machine groups for dynamic fleet comparisons

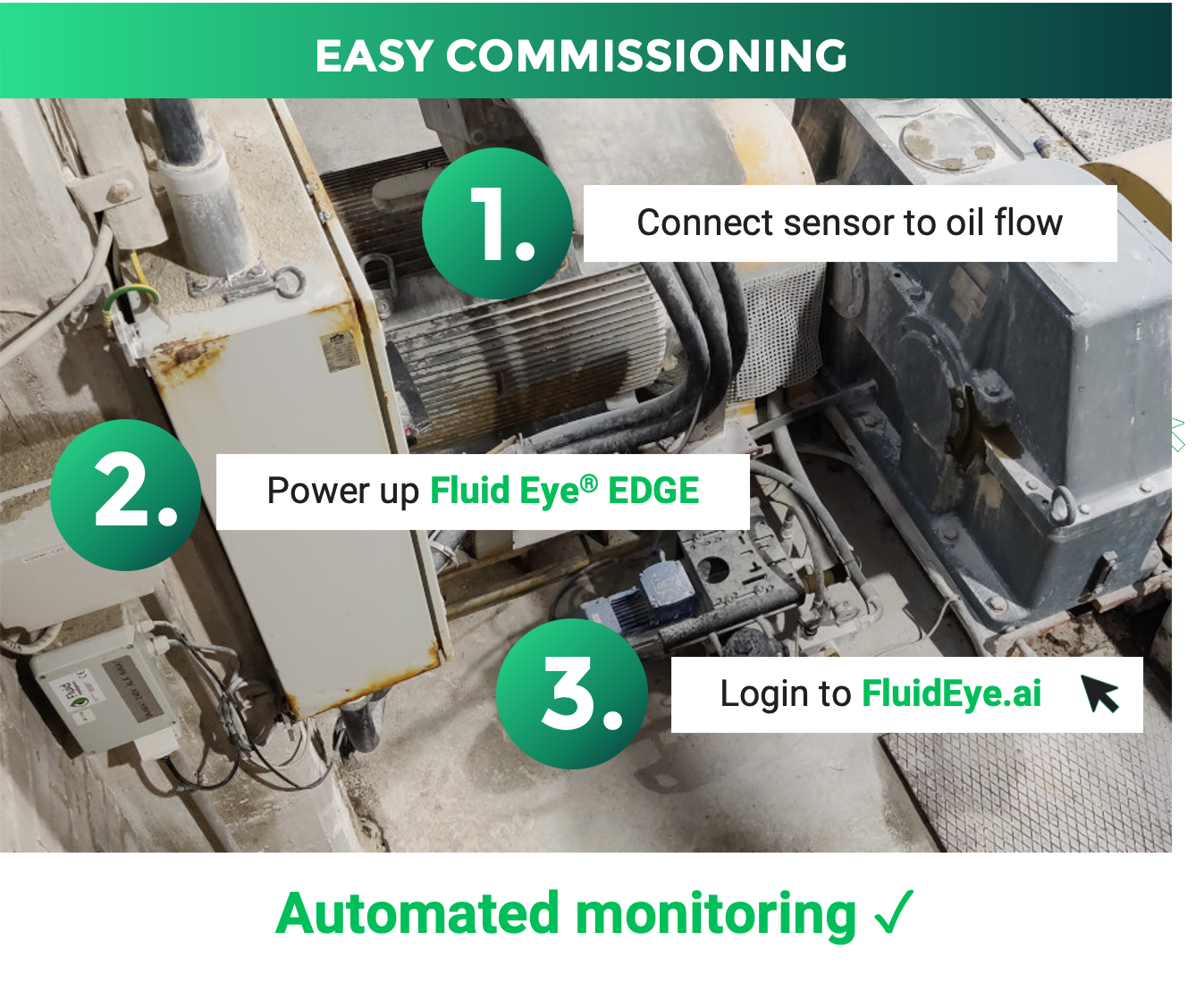

Connected Oil® Monitoring

Real-time Monitoring is a corner stone for ensuring critical assets and processes operational performance

Oil Condition Monitoring 24/7 real-time visibility for operational reliability and quality control

Analysis and Advice get instant alerts and actionable advice for proactive anomaly mitigation

Key parameters easy monitoring of fluid’s chemical, cleanliness and other key properties

-

Oil quality

Temperature

+ Pressure, flow, level

-

Particle counts & sizes

Particle classes

Humidity (rH%)

-

Water (ppm)

Oxidation

Antioxidants

TAN/TBN

Viscosity etc.

“Oil performance monitoring brings us real operational reliability and reduces our cost base.”

Ville Vesterinen, Technical Development Manager

Reconditioning and Services

Fluid Optimization benefits are achieved with timely actions along with suitable reconditioning machinery

Impurity removal effective way to remove solid and soft particles, water and soluble impurities (varnish)

Real-time Monitoring impurity removal units connected with monitoring guarantees success

Additive top-ups and Chemicals prevent oil aging, additive depletion and extend oil’s lifetime

Expert Services get tailored support in form of lab analysis, site and emission audits, and projects

Fluid Eye®

NTF Mini

Fluid Eye®

NTF Mobile

Fluid Eye®

+ VITA ESP II

“Fluid Intelligence successfully executed oil flushing from circulation water pump system at Olkiluoto OL3.”

Stephan Bachmeier, Site Manager, Siemens AG

Regeneration and CO2 offsets

The right recycling and residual emission compensation models complement the emission minimization goals

Waste Oil Regeneration minimize environmental impacts by selecting correct waste treatment site

CO2 offsets compensate final (mainly Scope 3) residual emissions with high quality emission credits

Emission Reporting get automated emission reports for your lube-based Scope 1-3 emissions for reporting compliance