Case Woikoski

Chemical industry

Connected Oil® detected an emerging bearing failure

Case compressor - Real-time oil performance monitoring

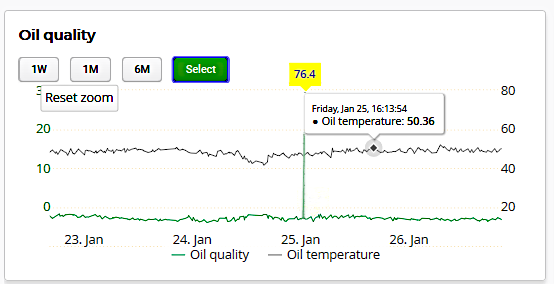

Image 1. Clearly noticeable deviation in oil performance trend

Fluid Monitoring combined with Tan Delta Oil Quality Sensor detected a deviation in the customer’s compressor monitoring data that was confirmed to be a bearing failure. Early failure detection enabled risk minimization and planned maintenance work during the production break.

Fluid Monitoring combined with Tan Delta Oil Quality Sensor alerted about oil performance trend deviation in late 2018. The deviations emerged as single high peaks in the gathered data trend line during the consecutive weeks.

ACTIONS

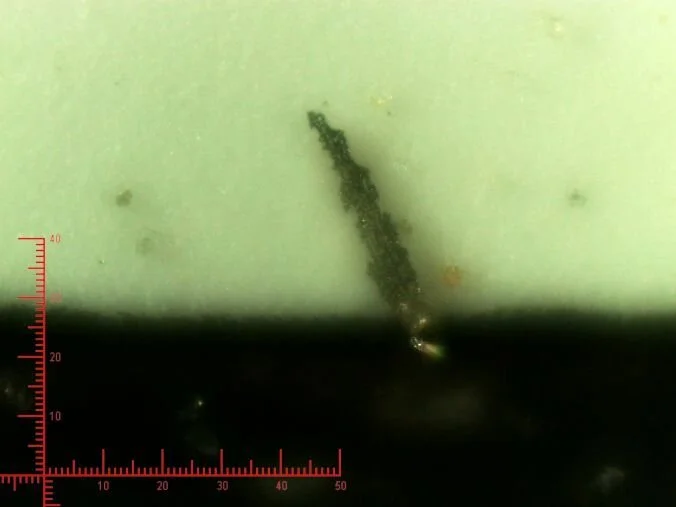

Maintenance team started more detailed inspection. In the beginning they carried out a vibration analysis that revealed slightly increased vibration levels and sound. Fluid Intelligence carried out an oil sampling and cleanliness analysis. The results revealed few 50-100 micron sized metal particles in the oil that were originated from sliding surfaces contacts.

Thorough root cause analysis indicated that there was a notable failure developing. However, it was possible to continue production until the next maintenance break. This procedure was also recommended by the machine manufacturer.

Image 2. Few but relatively large metal chips in an oil sample

Image 3. Long, over 100 micron chips indicated about notable failure mode development

The decision was made to increase the machine’s performance monitoring as it was part of the 24/7 production process. Fluid Monitoring alert levels were narrowed, regular oil sampling was implemented, as well as regular vibration analysis. Oil purity level was better than required during the whole process and oil side cycle filtration was performing as expected. In addition to these activities the customer started detailed maintenance break service planning.

Image 4. Bearing failure still in its infancy but clearly visible

A larger revision was implemented for this specific machinery during the normal maintenance break in summer of 2019. A shaft bearing damage was detected. The customer was able to fix the failure quickly during the normal maintenance break due to early failure and it’s type indication.

Woikoski Ltd. Ville Vesterinen (Technical Development Manager)

As a whole this event provides a school class example of well-functioning proactive maintenance. Oil performance monitoring brings us a real operational reliability and reduces our cost base.

NOTABLE OPERATIVE AND FINANCIAL CUSTOMER BENEFITS

Early failure detection let maintenance team to plan needed maintenance activities, acquire needed resources and spare parts well in advance

Connected Oil® enabled maintenance team to monitor failure mode escalation speed and make sure that any operation interruptions won’t happen before the next maintenance break

The customer was able to continue production after the risk analysis and no extra work were needed as the compressor could be repaired during the normal maintenance break

Maintenance work focused only on changing the bearing and no other damages occurred

Read more about Woikoski Oy

Read more about Fluid Intelligence services