Lubricating the Sustainable Future

More Uptime. Less Costs.

Net Zero Lubrication.

Customers across heavy industry and logistics sectors manage the lifecycle of lubricants with Fluid Eye®

Fluid Eye® – The Operating System For Lubricants

Manage the entire lubrication lifecycle — from lube planning and simulation to performance optimization and long-term operational impact.

All seamlessly orchestrated by Fluid Eye®, your operating system for industrial lubrication.

Three Steps to Lubrication Performance

Plan with Insight

Make smarter lubrication decisions before use — with simulations, real data, and structured planning tools.

Value Simulation

Forecast costs, CO₂ & lifecycle

Lube Planning

Build structured lube programs

Perform with Precision

Extend fluid life and machine health with real-time diagnostics and proactive optimization.

Connected Oil® Monitoring

24/7 IIoT monitoring

Lab & Oil Data Manager

Health Scores & benchmarks

Contaminant control

Filtration & impurity removal

Chemical enhancers

Additives & premium fluids

Expert projects

Diagnostics & audits

Extend the Impact

Close the loop with recovery, certified CO₂ offsets and fleet-to-enterprise reporting.

Lifecycle Advisory

Used oil regeneration & offsets

Reporting & Documentation

Cost, reliability & CO₂ reporting

Trusted by Industry Leaders Across Sectors

Fluid Eye® delivers measurable lubrication performance and sustainability across energy, logistics, heavy industry and more.

Energy & Utilities

Mining & Minerals

Process Industries

Paper, Pulp & Wood

Waste & Recycling

Logistics & Transport

Oil, Gas & Chemicals

OEM’s & Service Providers

Why Lube Lifecycle Management Matters?

Global industries face over $1 trillion in annual costs from unplanned downtime, machine failures, oil changes, and related maintenance - and over half of this is linked to lubrication.

Lubrication-related failures cost industries $250B in lost uptime and corrective actions — and another $250B is spent on oil changes and reactive maintenance, much of it unnecessarily.

Lubrication impacts reliability, efficiency, and emissions — yet it remains one of the most undervalued and underutilized assets in industrial operations today. It doesn’t have to be.

What is Net Zero Lubrication?

Lubrication is one of the few industrial systems that directly impact operational reliability, costs, and emissions.

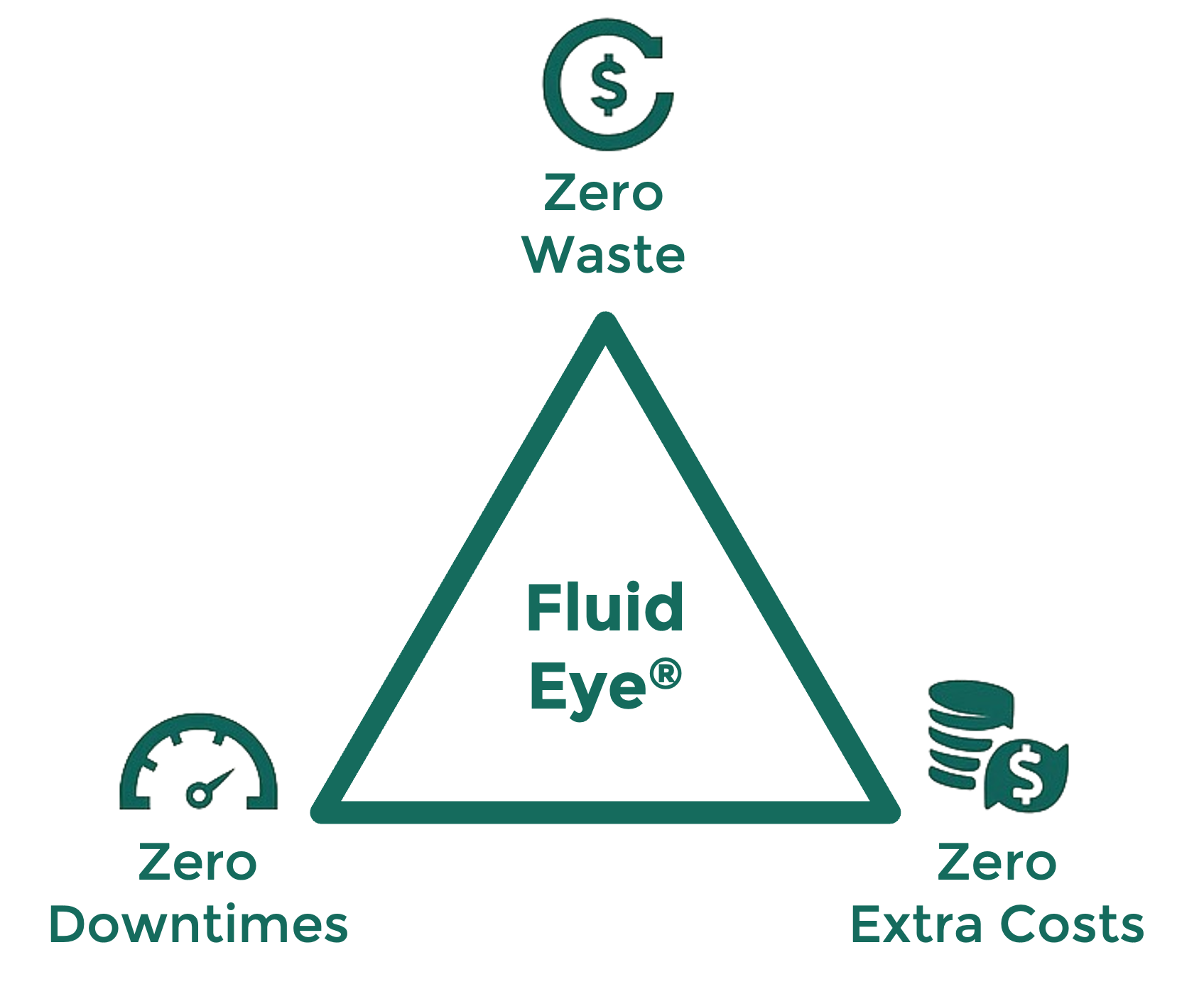

Net Zero Lubrication means reaching three outcomes at once:

Zero Downtime → maximum reliability and uptime

Zero Waste → extended oil life and minimized disposals

Zero Extra Costs → measurable savings in total cost of ownership

It’s made possible through our 3-step model:

#1 Plan with Insight, #2 Perform with Precision, #3 Extend the Impact.

With the right data, tools, and strategy, companies can cut emissions, reduce costs, and improve reliability — all in one system.

Optimizing Lubrication for Profits and the Planet

Fluid Intelligence helps industrial companies turn lubrication into a driver of productivity, reliability and sustainability.

Our Fluid Eye® platform and Net Zero Lubrication model enable full lifecycle optimization — from planning and diagnostics to in-service performance and end-of-life recovery.

We serve heavy industry, logistics, and process sectors, and integrate with OEMs and service providers to deliver measurable value across the supply chain.

-

1. What is Net Zero Lubrication?

Net Zero Lubrication means reaching three outcomes at once: Zero Downtime, Zero Waste and Zero Extra Costs. With the Fluid Eye® platform, industries can extend oil life, minimize waste and reduce emissions — while improving reliability and lowering total costs.2. How does Fluid Intelligence help companies achieve Net Zero Lubrication?

We provide the Fluid Eye® platform and Connected Oil® monitoring, combined with services for planning, diagnostics, optimization, lifecycle advisory and reporting. Together these cover the full lubrication lifecycle.3. What industries benefit from Fluid Intelligence solutions?

Our solutions serve heavy industry, logistics, energy, process and manufacturing sectors. We also work with OEMs and service partners to deliver lubrication reliability across fleets, plants and global operations.4. What services are included in your portfolio?

Fluid Intelligence offers end-to-end services:· Plan → Value Simulation, Lube Planning

· Perform → Connected Oil® Monitoring, Lab & Oil Data Manager, Lube Optimization

· Extend → Lifecycle Advisory, Reporting & Documentation

5. How do your solutions reduce CO₂ emissions?

By extending oil life, reducing waste oil, and enabling oil regeneration, our customers minimize their carbon footprint. Residual emissions can be offset with certified carbon credits, supporting Net Zero targets.6. How do your solutions cut costs for customers?

Our approach reduces unplanned downtime, extends lubricant life, and lowers maintenance expenses. Customers see measurable savings in total cost of ownership (TCO) while gaining reliability and sustainability benefits.7. What oil should I use?

The optimal oil depends on your equipment, load, temperature range, pressure levels and reliability targets. Instead of selecting oil purely by brand, it’s important to choose the right viscosity and technical performance properties for your system’s operating conditions — including cleanliness requirements, oxidation stability and additive balance.

With Fluid Eye® Lube Planner, you can compare options using real data and find the best-performing oil for your machines throughout the entire lifecycle.8. What is Fluid Eye®?

Fluid Eye® is the world’s first Operating System for Lubricants. It integrates planning, monitoring, diagnostics, optimization, lifecycle advisory and reporting into one system — providing full visibility and control across sites, fleets and enterprises.9. What is Connected Oil®?

Connected Oil® is our real-time oil condition monitoring solution. Using IIoT sensors and cloud analytics, it continuously tracks lubricant health, contamination, chemical changes and performance. This enables early detection of anomalies, predictive maintenance, and maximum uptime for critical assets.